Download Center

Wissen und Technik zum Mitnehmen

In unserem Download Center finden Sie aktuelle Broschüren, technische Berichte und Fachartikel rund um unsere Produkte und Entwicklungen. Ob detaillierte Informationen zum Comprex™-System oder spannende Einblicke in neue Projekte – hier stellen wir Ihnen alle wichtigen Dokumente gebündelt zur Verfügung.

Allgemeines Verständnis des Druckwellenprozesses

Um die verschiedenen Variationsmöglichkeiten für motorische Anwendungen verstehen zu können, braucht es ein

grundsätzliches Verständnis des Druckwellenprozesses im ComprexTM Druckwellenlader.

Antrova AG

-1_1.jpg)

Wasserstoffmotoren und das neue Comprex™ Druckwellenlader-Konzept

Wasserstoffmotoren sind entscheidend für zukünftige Emissionsstandards.

Ergebnisse aus dem Jahr 2020 von Prof. Eichlseder (Universität Graz) heben die Notwendigkeit der sequentiellen Turboladung hervor. Der Comprex™ Druckwellenlader mit integrierter sequentieller Aufladung, Motorbremse und Leistungsturbine ist dafür ideal geeignet.

Dieses Paper beschreibt das Konzept, seine Eignung für Wasserstoffmotoren sowie seine Rolle bei der Erreichung von ultra-niedrigen Emissionen und hoher Effizienz.

Antrova AG for 42nd International Vienna Motor Symposium 2021

Artikel in der Schweizer Automobil Revue

KOMPRESSOR In den 1990er-Jahren wäre es dem

Druckwellenlader beinahe gelungen, dem Turbolader den Rang

abzulaufen. Technische und finanzielle Hürden liessen ihn aber

scheitern. Jetzt könnte er doch noch erfolgreich werden.

Schweizer Automobil Revue

Hydrogen engines and the new Comprex™ pressure wave supercharger concept

Wasserstoffmotoren gelten als Schlüssel zur Einhaltung künftiger Umweltvorgaben.

Prof. Eichlseder (Uni Graz, 2020) betont die Notwendigkeit sequentieller Aufladung. Der Comprex™ PWS erfüllt dies mit integriertem Ladesystem, Motorbremse und Turbine.

Diese Arbeit zeigt das Konzept sowie Vorteile bei Emissionen, Effizienz und Ansprechverhalten.

Antrova AG

.jpg)

Comparison of Turbocharging and Pressure Wave Supercharging of a Natural Gas Engine for Light Commercial Trucks and Vans

A Miller camshaft with a Comprex™ supercharger boosted natural gas engine torque by 49% at 1250 rpm and improved transient response by 2.5x over a turbo.

Water injection increased peak power within thermal limits.

Comprex™ reduced friction brake use by two-thirds and sped up catalyst warm-up 6x.

A complete redesign resolved previous Comprex™ drawbacks.

Norbert Zsiga 1, Mario A. Skopil 2, Moyu Wang 1, Daniel Klein 3 and Patrik Soltic 1

1 Automotive Powertrain Technologies Laboratory, Empa Swiss Federal Laboratories for Materials Science and Technology, 8600 Dübendorf, Switzerland; moyu.wang@empa.ch (M.W.); patrik.soltic@empa.ch (P.S.)

2 Antrova AG, Hofwisenstrasse 13, 8260 Stein am Rhein, Switzerland; mario.skopil@antrova.com

3 FPT Motorenforschung AG, Schlossgasse 2, 9320 Arbon, Switzerland; daniel.klein@fptindustrial.com

Automotive Solutions aus der Schweiz

Automotive Solutions aus der Schweiz --> Antrova AG

Antrova AG

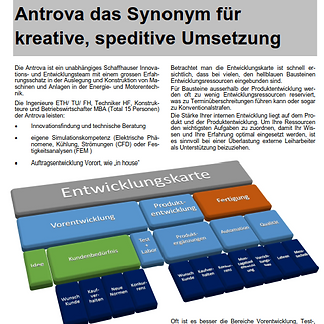

Antrova das Synonym für kreative, speditive Umsetzung

Antrova das Synonym für kreative, speditive Umsetzung

Antrova AG

New boosting concept for a methane-powered engine

Pressure wave superchargers (Figure 1) use pressure waves of the exhaust gases to compress fresh air in the cells of the rotor. The rotor turns, driven by electric motor, so this process can be synchronized. Due to the principle that exhaust gases are compressing fresh air in direct contact, the rotor speed can also be used to control exhaust gas recirculation. In engines working at λ=1 principle the three-way-catalyst needs to be located before boosting device, which can have a positive impact on its performance, for example during cold start.

Empa Materials Science and Technology

Simulation, Rechenschieber der heutigen Zeit?

Simulation, Rechenschieber der heutigen Zeit?

Antrova AG

Ein neues Druckwellenladerkonzept für weniger Emissionen und mehr Effizienz

The Pressure Wave Supercharger (PWS) is an alternative to turbo- and supercharging. This paper presents a new concept addressing key issues of earlier designs, especially temperature-sensitive rotor gaps and limited controllability in petrol and gas engines.

Improvements are achieved through a revised bearing system with a water-cooled exhaust housing, a centrally split rotor, and the option to deactivate one gas-dynamic cycle, similar to register charging. Advantages over previous systems, as well as general benefits for efficiency and emissions, are discussed.

Antrova AG

A new Pressure Wave Supercharger concept for less emissions and more efficiency

How does a Pressure Wave Supercharger work and why use it?

Antrova AG

Erfahrung in der Hochspannung mit über 15 Patenten

tions- und Entwicklungsteam mit einem grossen Erfahrungsschatz in der Auslegung und Konstruktion von

Hochspannungs- und Hochstromkomponenten, sowie Anlageteilen.

Antrova heisst:

• Ingenieure ETH/ TU/ FH, Techniker HF, Kon-

strukteure, Betriebswirtschaftler MBA (15 Per-

sonen)

• eigene Simulationskompetenz (Erdung, Feldverteilung, Stromverteilung, Dielektrik, Kühlung, CFD

oder FEM )

• Erfahrungen in:

- Nennspannung <1kV bis 800kV

- Nennstrom bis 30kA

• Vorort- wie auch Projektarbeiten

• SVTI geprüfte Anlagen

Antrova AG

EVOLUTION of the Pressure Wave Supercharger Concept

Abstract: Das Konzept der Druckwellenaufladung besteht seit über hundert Jahren und entwickelte sich zunächst langsam, erlebte aber in den letzten Jahrzehnten einen beschleunigten Fortschritt. Dieser Artikel gibt einen Überblick über die Forschungsergebnisse zur Druckwellentechnologie und deren Anwendung in der Motoraufladung.

Die Arbeit ergänzt frühere Berichte, zeigt die Entwicklung von Konzept und Technik sowie die Bemühungen, spezifische Schwächen der Druckwellen-Technologie zu beheben. Druckwellenrotoren waren lange ein Forschungsschwerpunkt. Früher dominierten experimentelle Studien, da theoretische Berechnungen komplex waren. Moderne Computersimulationen, präzise Messinstrumente und Diagnosetechniken eröffnen heute neue Innovationsmöglichkeiten.

Abschließend werden aktuelle Herausforderungen und zukünftige Forschungsfelder aufgezeigt.

To cite this article: Iuliana Costiuc and Anghel Chiru 2017 IOP Conf. Ser.: Mater. Sci. Eng. 252 012081

Comprex™— Verpasste Chancen

Entwicklung ist ein digitaler Prozess, vergleichbar mit einer Serie situativer Weichenstellungen. Diese führen nicht immer zum optimalen Ergebnis – oft bleiben gute, teils ungewöhnliche Ideen ungenutzt. Hätte man sie aufgegriffen, wäre vieles anders verlaufen.

Ein Beispiel ist der Comprex. Die Schweiz war ein Pionierland der Aufladung: Nach Büchi (1905) brachte BBC 1942 Lader industriell in Lkw mit Holzvergasermotoren ein. Doch diese waren groß und erzeugten ein Turboloch. 1945 setzte Seippel erstmals den verzögerungsfreien Comprex als Oberstufe einer Gasturbine ein – ein Impuls für neue Ideen. 1956 übertrug Berchtold das Prinzip auf Lkw-Motoren und bewies: perfektes Fahrverhalten bei gutem Verbrauch.

MTZ - Motortechnische Zeitschrift volume 78, page90 (2017)

Der falsche Ort für den Rotstift

Wenn in einem Unternehmen gespart werden muss, wird der Rotstift oft auch beim Entwicklungsbudget angesetzt. Ein Schritt, bei dem Unternehmen nicht selten Gefahr laufen, vom Innovationsführer zum Nachahmer zu werden.

Schaffhauser Nachrichten 21.12.2011

DESIGN AND SIMULATION OF A PRESSURE WAVE SUPERCHARGER FOR A

SMALL TWO-STROKE ENGINE

As small remotely piloted aircraft become more common for aerial observation, there is a growing need to improve their performance. High-altitude low pressures reduce the efficiency of small engines typically used in these aircraft. The best way to recover lost performance is by adding forced induction.

A special type of wave rotor, the Pressure Wave Supercharger, can avoid many scaling losses and operate efficiently for small engines. This thesis details the design and computational simulation of a Pressure Wave Supercharger for a 95 cc Brison engine.

Using a NASA quasi-1D CFD code, performance predictions for a Comprex® Pressure Wave Supercharger were made and compared with measurements. Based on this, a scaled-down version was designed, modeled in CAD, manufactured, and tested on a dedicated rig.

This device boosts intake manifold pressure to at least atmospheric levels, improving the performance of small two-stroke engines at high altitude. This enables small unmanned aerial systems used by the Air Force to fly higher and enhance mission effectiveness.

DEPARTMENT OF THE AIR FORCE

AIR UNIVERSITY

Comprex bläst den Turbo weg

Zwei Audi 80 mit 70 PS starken Dieselmotoren stehen an der Startlinie. Der einen ein serienmässiges Modell mit Abgas- Turbolader, der andere wird vom neuen Comprex System auf Trab gebracht. Auto Bild nahm die beiden Dieselspinter unter die Lupe.

Auto Bild 09.06.1986 Seite 6

A Review of Wave Rotor

Technology and Its Applications

This paper provides a brief review of past and current research on wave rotor technology, which uniquely enhances performance in engines and machinery using thermodynamic cycles. Despite various applications, the technology remains little known and rarely used by engineers.

The review summarizes earlier work and ongoing global efforts, covering wave rotor applications from early experiments to commercial superchargers for car engines, gas turbine topping, and other advances. It also highlights recent developments in pressure-gain combustors, ultra-micro gas turbines, and water refrigeration systems, pointing to future research directions.

Insights from experiments, simulations, analytical methods, and design tools are presented.

Department of Mechanical Engineering, Purdue School of Engineering and Technology, Indianapolis, IN 46202-5132

Werkstatthandbuch Senator A2 Comprex D

Der Comprex-Druckwellenlader nutzt wie der Turbolader die Abgasenergie, baut den Ladedruck aber direkt auf, ohne diese in mechanische Energie umzuwandeln. Dadurch reagiert der Motor verzögerungsfrei auf Lastwechsel, mit einem deutlich günstigeren Drehmomentverlauf, besonders beim Beschleunigen.

Zwischen 1.400 und 3.700 U/min sind etwa 90 % des maximalen Drehmoments verfügbar. Der 2,3-Liter-Diesel erreicht mit Comprex 95 PS bei 4.200 U/min und 195 Nm bei 2.200 U/min. So schafft der Senator Comprex D 172 km/h Höchstgeschwindigkeit und 0–100 km/h in 15 Sekunden.

Opel Senator A2 Comprex D 2.3l

The Comprex....A New Concept of Diesel Supercharging

The Comprex supercharger compresses air by direct transmission of energy from an expanding gas tilizing compression and expansion waves. The name Comprex is a contraction of Compression-Expander. Although the phenomena of nonsteady flow have been studied extensively in connection with explosions, diesel fuel injection, railway airbrakes, water hammer, safety equipment in hydraulic power stations, and so on, the use of these effects in gases is relatively new. This paper deals with the Comprex as applied to supercharging of internal-combustion engines. It explains the principle of operation, describes the design and discusses the particular operational characteristics as a supercharger for a 4-cycle diesel engine. It should be remembered that this is only one of many applications of a broad and unexploited field.

Contributed by the Gas Turbine Power Division for presentation at the Gas Turbine Power Conference and Exhibit, Washington, D. C., March 2-6, 1958, of THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS. (Manuscript received at ASME Headquarters, January 16, 1958.)