Download Center

Knowledge and Technology to Go

In our Download Center, you will find up-to-date brochures, technical reports, and specialist articles about our products and developments. Whether detailed information on the Comprex™ system or exciting insights into new projects here we provide all important documents conveniently bundled for you.

General Understanding of the Pressure Wave Process

To understand the different variations possible for engine applications, a fundamental understanding of the pressure wave process in the Comprex™ pressure wave supercharger is necessary.

Antrova AG

-1_1.jpg)

Hydrogen engines and the new Comprex™ pressure wave supercharger concept

Hydrogen engines are key to future emissions standards. 2020 findings by Prof. Eichlseder (Univ. Graz) highlight the need for sequential turbocharging. The Comprex™ PWS, with built-in sequential charging, engine brake, and power turbine, is ideally suited. This paper outlines the concept, its fit for hydrogen engines, and its role in achieving ultra-low emissions and high efficiency.

Antrova AG for 42nd International Vienna Motor Symposium 2021

Article in the Swiss Automobile Review

Compressor in the 1990s, the pressure wave supercharger nearly succeeded in overtaking the turbocharger. However, technical and financial hurdles caused its failure. Now, it might still become successful after all.

Schweizer Automobil Revue

Hydrogen Engines and the New Comprex™ Pressure Wave Supercharger Concept

Hydrogen engines are considered key to meeting future environmental regulations.

Prof. Eichlseder (Uni Graz, 2020) emphasises the need for sequential charging. The Comprex™ PWS meets this with an integrated charging system, engine brake, and turbine.

This paper presents the concept as well as the benefits regarding emissions, efficiency, and responsiveness.

Antrova AG

.jpg)

Comparison of Turbocharging and Pressure Wave Supercharging of a Natural Gas Engine for Light Commercial Trucks and Vans

A Miller camshaft with a Comprex™ supercharger boosted natural gas engine torque by 49% at 1250 rpm and improved transient response by 2.5x over a turbo.

Water injection increased peak power within thermal limits.

Comprex™ reduced friction brake use by two-thirds and sped up catalyst warm-up 6x.

A complete redesign resolved previous Comprex™ drawbacks.

Norbert Zsiga 1, Mario A. Skopil 2, Moyu Wang 1, Daniel Klein 3 and Patrik Soltic 1

1 Automotive Powertrain Technologies Laboratory, Empa Swiss Federal Laboratories for Materials Science and Technology, 8600 Dübendorf, Switzerland; moyu.wang@empa.ch (M.W.); patrik.soltic@empa.ch (P.S.)

2 Antrova AG, Hofwisenstrasse 13, 8260 Stein am Rhein, Switzerland; mario.skopil@antrova.com

3 FPT Motorenforschung AG, Schlossgasse 2, 9320 Arbon, Switzerland; daniel.klein@fptindustrial.com

Automotive Solutions from Switzerland

Automotive Solutions from Switzerland — Antrova AG

Antrova AG

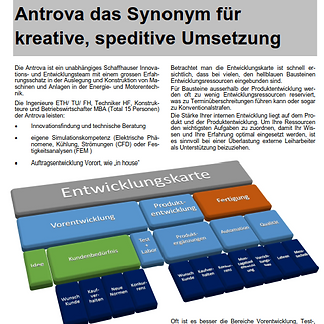

Antrova: The synonym for creative, efficient execution

Antrova: The synonym for creative, swift execution

Antrova AG

New boosting concept for a methane-powered engine

Pressure wave superchargers (Figure 1) use pressure waves of the exhaust gases to compress fresh air in the cells of the rotor. The rotor turns, driven by electric motor, so this process can be synchronized. Due to the principle that exhaust gases are compressing fresh air in direct contact, the rotor speed can also be used to control exhaust gas recirculation. In engines working at λ=1 principle the three-way-catalyst needs to be located before boosting device, which can have a positive impact on its performance, for example during cold start.

Empa Materials Science and Technology

A new pressure wave supercharger concept for lower emissions and greater efficiency

The Pressure Wave Supercharger (PWS) is an alternative to turbo- and supercharging. This paper presents a new concept addressing key issues of earlier designs, especially temperature-sensitive rotor gaps and limited controllability in petrol and gas engines.

Improvements are achieved through a revised bearing system with a water-cooled exhaust housing, a centrally split rotor, and the option to deactivate one gas-dynamic cycle, similar to register charging. Advantages over previous systems, as well as general benefits for efficiency and emissions, are discussed.

Antrova AG

A new Pressure Wave Supercharger concept for less emissions and more efficiency

How does a Pressure Wave Supercharger work and why use it?

Antrova AG

Experience in High– Voltage Technology with over 15 Patents Registered

Antrova is a independent innovation and development company located in Schaffhausen Switzerland.

Over the last 15 years, Antrova has acquired a deep knowledge in dimensioning and construction of high current and high voltage components and facilities.

Antrova offers:

- engineers PHD/ Master/ Bachelor, technical designer, business economist MBA

- own simulation capabilities (grounding , field distribution, current distribution, dielectric, cooling , CFD and FEM )

Experience in:

- nominal voltage up to 800kV

- nominal current up to 30kA

- work on-site and project work

- system parts certified by SVTI (Swiss association for technical inspection)

Antrova AG

EVOLUTION of the Pressure Wave Supercharger Concept

Abstract: The concept of pressure wave supercharging has existed for over a hundred years and initially developed slowly, but has experienced accelerated progress in recent decades. This article provides an overview of research findings on pressure wave technology and its application in engine charging.

The paper complements earlier reports, showcasing the development of the concept and technology, as well as efforts to address specific weaknesses of pressure wave technology. Pressure wave rotors have long been a focus of research. Previously, experimental studies dominated due to the complexity of theoretical calculations. Modern computer simulations, precise measurement instruments, and diagnostic techniques now open up new possibilities for innovation.

Finally, current challenges and future research areas are outlined.

To cite this article: Iuliana Costiuc and Anghel Chiru 2017 IOP Conf. Ser.: Mater. Sci. Eng. 252 012081

Comprex™ — Missed Opportunities

Development is a digital process, comparable to a series of situational decisions. These don’t always lead to the optimal result – often good, sometimes unusual ideas remain unused. Had they been pursued, many things would have turned out differently.

One example is the Comprex. Switzerland was a pioneer in forced induction: after Büchi (1905), BBC introduced superchargers industrially in trucks with wood gas engines in 1942. However, these were large and caused turbo lag. In 1945, Seippel was the first to use the lag-free Comprex as a top stage on a gas turbine – a stimulus for new ideas. In 1956, Berchtold applied the principle to truck engines and demonstrated perfect driving behaviour with good fuel consumption.

MTZ - Motortechnische Zeitschrift volume 78, page90 (2017)

The Wrong Place for the Red Pen

When a company needs to cut costs, the development budget is often targeted with the red pen. A move that can all too often turn a company from an innovation leader into a follower.

Schaffhauser Nachrichten 21.12.2011

DESIGN AND SIMULATION OF A PRESSURE WAVE SUPERCHARGER FOR A

SMALL TWO-STROKE ENGINE

As small remotely piloted aircraft become more common for aerial observation, there is a growing need to improve their performance. High-altitude low pressures reduce the efficiency of small engines typically used in these aircraft. The best way to recover lost performance is by adding forced induction.

A special type of wave rotor, the Pressure Wave Supercharger, can avoid many scaling losses and operate efficiently for small engines. This thesis details the design and computational simulation of a Pressure Wave Supercharger for a 95 cc Brison engine.

Using a NASA quasi-1D CFD code, performance predictions for a Comprex® Pressure Wave Supercharger were made and compared with measurements. Based on this, a scaled-down version was designed, modeled in CAD, manufactured, and tested on a dedicated rig.

This device boosts intake manifold pressure to at least atmospheric levels, improving the performance of small two-stroke engines at high altitude. This enables small unmanned aerial systems used by the Air Force to fly higher and enhance mission effectiveness.

DEPARTMENT OF THE AIR FORCE

AIR UNIVERSITY

Comprex blows the turbocharger away

Two Audi 80s with 70 hp diesel engines line up at the starting line. One is a standard model with an exhaust turbocharger, while the other is powered by the new Comprex system. Auto Bild put both diesel sprinters to the test.

Auto Bild 09.06.1986 Seite 6

A Review of Wave Rotor

Technology and Its Applications

This paper provides a brief review of past and current research on wave rotor technology, which uniquely enhances performance in engines and machinery using thermodynamic cycles. Despite various applications, the technology remains little known and rarely used by engineers.

The review summarizes earlier work and ongoing global efforts, covering wave rotor applications from early experiments to commercial superchargers for car engines, gas turbine topping, and other advances. It also highlights recent developments in pressure-gain combustors, ultra-micro gas turbines, and water refrigeration systems, pointing to future research directions.

Insights from experiments, simulations, analytical methods, and design tools are presented.

Department of Mechanical Engineering, Purdue School of Engineering and Technology, Indianapolis, IN 46202-5132

Workshop Manual Senator A2 Comprex D

The Comprex pressure wave supercharger, like the turbocharger, utilises exhaust energy but builds boost pressure directly without converting it into mechanical energy. This allows the engine to respond instantly to load changes, with a significantly improved torque curve, especially during acceleration.

Between 1,400 and 3,700 rpm, around 90% of the maximum torque is available. The 2.3-litre diesel achieves 95 hp at 4,200 rpm and 195 Nm at 2,200 rpm with the Comprex. This enables the Senator Comprex D to reach a top speed of 172 km/h and accelerate from 0 to 100 km/h in 15 seconds.

Opel Senator A2 Comprex D 2.3l

The Comprex....A New Concept of Diesel Supercharging

The Comprex supercharger compresses air by direct transmission of energy from an expanding gas tilizing compression and expansion waves. The name Comprex is a contraction of Compression-Expander. Although the phenomena of nonsteady flow have been studied extensively in connection with explosions, diesel fuel injection, railway airbrakes, water hammer, safety equipment in hydraulic power stations, and so on, the use of these effects in gases is relatively new. This paper deals with the Comprex as applied to supercharging of internal-combustion engines. It explains the principle of operation, describes the design and discusses the particular operational characteristics as a supercharger for a 4-cycle diesel engine. It should be remembered that this is only one of many applications of a broad and unexploited field.

Contributed by the Gas Turbine Power Division for presentation at the Gas Turbine Power Conference and Exhibit, Washington, D. C., March 2-6, 1958, of THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS. (Manuscript received at ASME Headquarters, January 16, 1958.)